|

I am a model builder just like you.

I started model railroading on a special Christmas

morning when I received my first train set. I had lots of fun on a sheet of

4 x 8 plywood. I quickly went from plastic kits to wood, and fell in love with

structures. After mastering craftsman kits I began scratch-building my own. As

an adult, in 1983, I began fooling around with Hydrocal, trying to create my own

scale masonry.

My first attempts were rather crude, something akin to

what a drunken mason might do with warped cinder blocks. It was pretty bad. But

I persevered and by applying drafting techniques I learned to carefully control

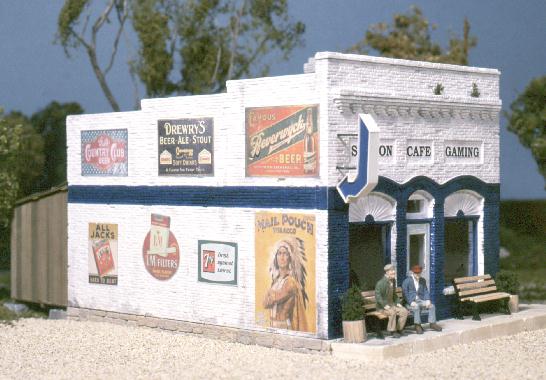

my efforts and create very precise renditions. My HO scale brick faces

are a scale 3" x 9", just slightly larger than the typical 2-1/4" x 8-1/2"

measurement but add a mortar line and we are right on. I even scribe the header

courses. I believe my hand-scribed brick is truly a work of art! Especially when

you add three more walls, doors and windows, brick arches and other three

dimensional details.

Next I tackled stone. It is a little freer than precise

scale brick but there are still some rules. I borrowed Jack Work's method for

creating Fractured Stone patterns and made all sorts of bridge abutments

and piers with then. I also hand-carved several variations of stone

walls on 4" x 8", 1/4" thick, panels.

After spending up to 24 hours on a single pattern the

next step is to make a rubber mold so we can recreate our hard work.

I use Dow Corning's 3110 RTV Silicone Rubber, a two part

system that cures at room temperature, shrinks very little and will give hundreds,

if not thousands of pulls. This was really a key element in my model

building. It took something that was very precious, that I wouldn't otherwise

dare to even attempt to mess with (try coloring, cut up into something else, or

even touch!) into something that I didn't have to worry about- if I screwed up

I could simply cast another one.

This opened up all sorts of possibilities from

experimenting with coloration to cast bashing my heart out.

Quickly I was learning how to work with my stock castings and developing my

favorite techniques. Hydrocal really is a dynamic material. Not only is it a

very strong castible material but it is easily cut and shaped. When I cut a

corner (no, not take a shortcut- I mean literally cut the corner of a brick wall),

or cut a window or door opening, I can then scribe the mortar lines around the

corners and make the wall truly three-dimensional. This is far

superior to what you might do with printed or embossed brick, and so far I

have not seen a 3D laser (not that I want to!), they are two-dimensional machines.

Sure, they can do cool things but not this cool!

Since beginning this adventure I have written about two

dozen and counting construction articles that have been published.

To see a list of them click

CONSTRUCTION ARTICLES .

Most have been published in Bob Hundman's Mainline Modeler with

others in The Narrow Gauge and Shortline Gazette and Model

Railroader. And hopefully there are many more to come.

Occasionally I present slide show clinics at

local and nation train shows. Usually these include my History of Masonry

Construction in North America, at least how I see it and my Fine

Art of Hydrocal Structure Modeling in basic and advanced varieties. If

I plan to present a clinic soon the following link will be active:

NEXT LIVE CLINIC.

I must say something about copyrights. The key ingredient to

all of this is the pattern work. It is unlawful to make copies of other peoples

pattern work with out their permission. Even if it is just for your own personal

use. I'm selling these castings to be used in a model. I am not selling you the

copyright. The price for that would be much higher. I used to express a looser view

on this (for personal use) however when I see my patterns under someone else's

packaging at a swap meet, hanging in a hobby shop, advertised in national publications,

and see modeling articles published that skip the critical part about making your

own masters, well, I need to speak firmly against all piracy. Please, make your

own patterns. Contribute something to the hobby, don't steal it.

Below, you will find a list of modest on line how to

clinics that I am in the process of developing. I hate it when web things

are "under construction", especially, when the site has been up for months,

if not years, and nothing has been added- but I promise, I will be adding more

of these. And improving them so please do check back. At least the basics will

be covered in the beginning. I'm sure you will enjoy them!

|

Builders In Scale

Builders In Scale

Home List Top

Home List Top

Crow's How 2

Crow's How 2

Availability

Availability

Order Crow's

Order Crow's

Contact CCC

Contact CCC